Quality

Quality is our foundation. We implement rigorous quality control at every stage – from raw material inspection to final product testing. Our plaster and concrete lighting undergoes durability, electrical safety, and performance checks, ensuring premium quality that meets international standards.

Quality Assurance

Premium materials ensure lasting durability in every lighting fixture we create.

Our integrated quality management system maintains efficiency across all production stages.

Each product undergoes multiple rigorous inspections and quality checks before shipment.

Our Product Testing and Inspection

Our products pass various tests to produce high-quality and reliable gypsum & concrete products. Some of them are listed below.

Light Source Testing – Electronics Performance Testing – Environmental Durability Testing – Product Reliability Testing – Packaging Durability Testing – Appearance Inspection – Dimensional Accuracy Inspection – Outgoing Inspection

Light Source Testing

Our lighting testing process evaluates key metrics including color rendering index (CRI), color temperature, luminous flux, and power efficiency. Each unit undergoes 30-minute preheating followed by 60-minute stabilized operation testing. Any non-conforming products result in full batch rejection.

Electronics Performance Testing

Our electronic drivers undergo comprehensive testing for voltage, current, power efficiency, and safety features including overload protection, surge resistance, and insulation integrity. Any components failing to meet standards are immediately rejected before production.

Environmental Durability Testing

We test product resilience under extreme conditions – from 85°C/95% humidity to -25°C environments – ensuring reliable performance across diverse climates. Each 2-hour thermal cycle validates durability, with full batch rejection for any failures.

Product Reliability Testing

We conduct thorough aging tests on all gypsum and concrete lights to ensure long-term stability. Each unit undergoes a 2-hour burn-in period to eliminate early failures, while our quality team verifies color temperature and illumination consistency before shipment.

Packaging Durability Testing

This test simulates potential impacts during shipping by dropping packages from specified heights: 1M for <5kg, 0.7M for <10kg, and 0.5M for <20kg items. Each unit undergoes comprehensive corner, edge, and surface impact tests, with thorough inspection of physical integrity and electrical function afterward. Any damaged units are immediately removed from production.

Appearance Inspection

Following strict company standards and reference samples, we examine each product’s appearance. Items not meeting our criteria are either repaired or discarded to ensure only perfect products reach our customers.

Dimensional Accuracy Inspection

We verify product dimensions against company standards and reference samples, conducting trial assembly with matching components. Any non-conforming items undergo repair or are systematically discarded.

Finished Product Inspection/ Outgoing Inspection

We conduct comprehensive inspections based on company standards and reference samples, examining appearance, structure, electro-optical performance, and packaging. Any batches failing to meet requirements undergo reworking to ensure quality compliance.

Enterprise Management System

We have established a mature and perfect enterprise quality management system, which can achieve high efficiency and high quality in all aspects of the operation.

Sales Development and After sales Service Management Procedure

Employee Recruitment and Training Management Procedure

Employee Promotion and Transfer Management Procedure

Employee Performance Appraisal Management Procedure

R&D and Design Management Procedures

Product Experimental Testing Management Procedure

PMC Plan Management Procedure

Procurement Management Procedure

Incoming Inspection Management Procedure

Process Inspection Management Procedure

Finished Product Inspection Management Procedure

Production and Processing Management Procedures

Warehouse Receipt and Shipment Management Procedure

Quality Record Form

Management Procedure for Handling Defective Products

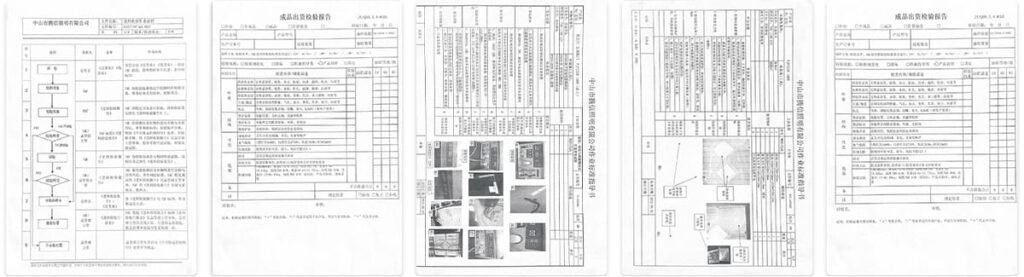

Incoming Inspection Process

Finished Product Inspection Report

Standard Execution Book

Standard Execution Book

Finished Product Inspection Report

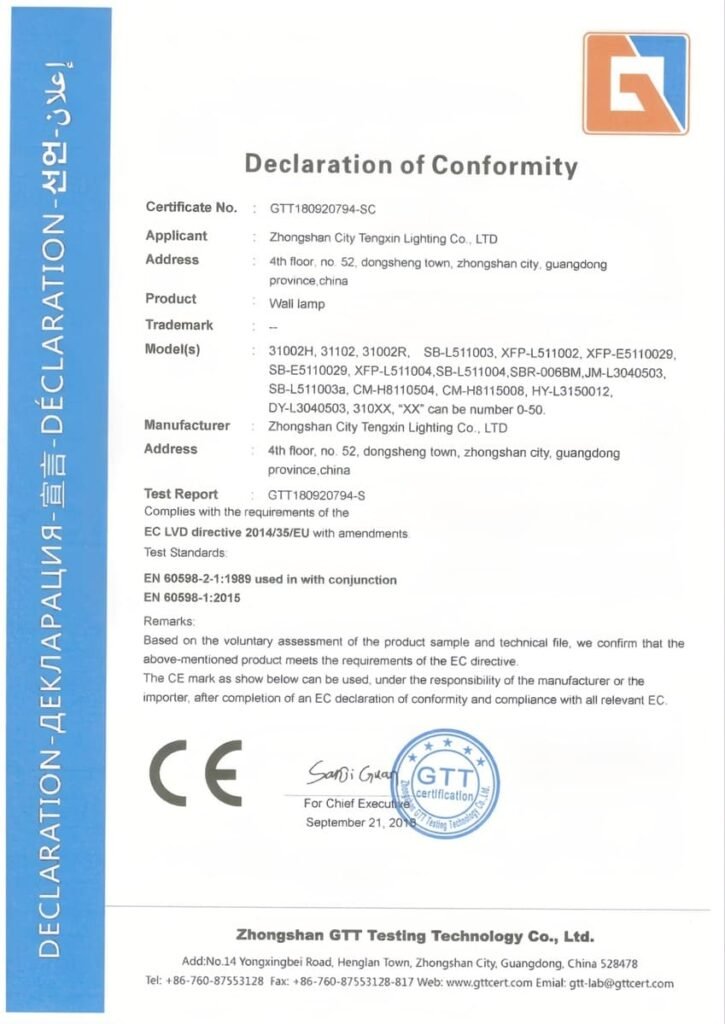

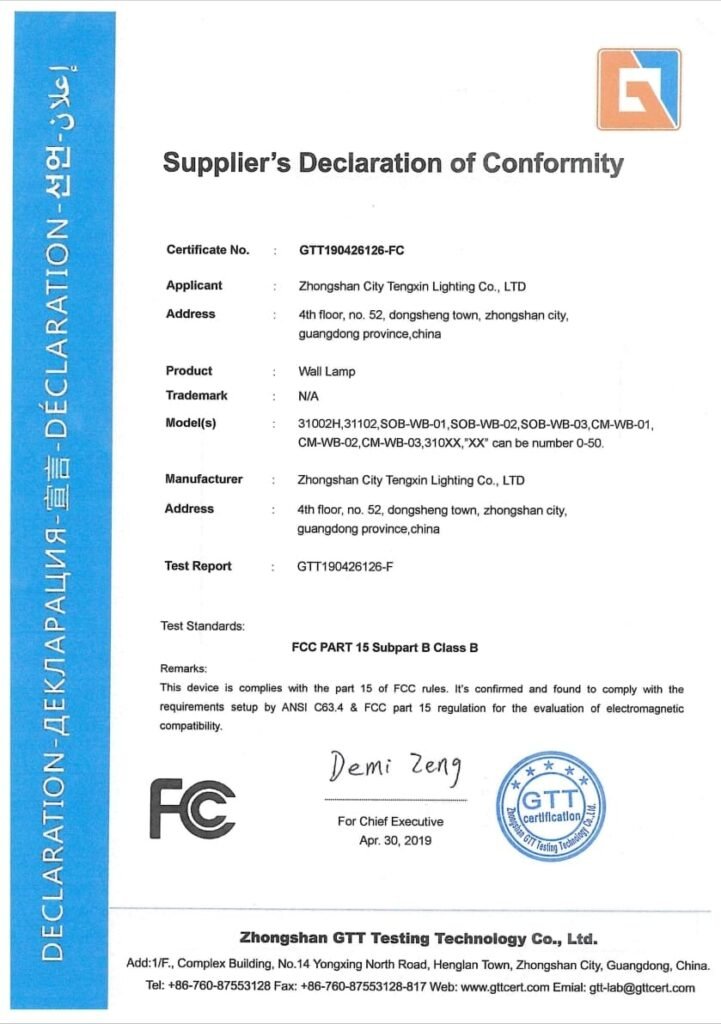

Certifications

Need an Instant Quote For Your Upcoming Projects?

Send us the details and we will get back to you within 12 hours.